1993 to 1995 F-Body Alarm Install Guide

1993 to 1995 F-Body Alarm Install Guide

Well, it's been quite some time since I put this page up and I

have yet to get

around to putting up a guide for the 93 to 95 F-Body and it doesn't look like

I'm going to get to it anytime soon. In the meantime, I've put together a zip

file of just the data that an alarm installer would use. It's not very

detailed but

will get you started and help you out. The only real major difference between

the 93 to 95 and 96+ is the way the door locks are handled and the need to

"wake up" the BCM. With that in mind, I think you can use this zip

file in

combination with the 96+ guide and not have any trouble! Good luck!

http://www.bfranker.badz28.com/fbody/93to95fbody.zip

1996 to 1998 F-Body Alarm Install Guide

1996 to 1998 F-Body Alarm Install Guide

Understanding Relays

It's going to be obvious that I scanned in the

following images out of an expensive installation book that I purchased. I called

the makers of the book a couple times asking if I could use some pics for this page I'm

making and each time they said they'd get back with me. Well, they never did so I'm

saying that's an implied "Yes"... right? :) Anyway, this is a small time

web page and I'm not making any money off of it so I don't think anybody is really going

to care too much. In the unlikely event that they find out about this and ask me to

take it off, I guess I'll just have to spend some time and make up my own drawings :)

A relay is an electromechanical switching device:

when both power and ground are applied to the ends of a coil, the relay activates,

which causes mechanical contact points to complete or open a circuit. One of the

relay's best features is its ability to use a very small amount of current to switch large

amounts of current. This ability helps to make the modern vehicle's electrical

system as efficient as it is. When an electrical current flows through a wire, the

wire has resistance, which limits the flow. The longer the wire is, more electrical

current is lost to this resistance. Devices such as headlights or climate control

systems require large amounts of current. Their efficiency drops dramatically with

just a small amount of current drop. A relay allows the circuit to be routed in the

shortest, most direct route between the battery, or source, and the device, or load.

A much smaller wire is routed to the relay from the controlling switch. This

arrangement allows for less total wire length, a smaller gauge wire and more reliable,

less expensive switches.

A standard Single Pole Double Throw (SPDT) automotive

relay's coil requires approximately between 130 and 170 milliamps (mA) to activate

(between 1 and 2 tenths of an amp), and the Normally Closed contacts will switch 30 amps,

and the Normally Open contacts 40 amps. Some manufacturers add a

"quenching" resistor across the coil of the relay to absorb voltage spikes.

These relays with the "quenching" resistor may need up to 170 milliamps

(mA) to activate. On the average, most relays require about 150 mA to activate.

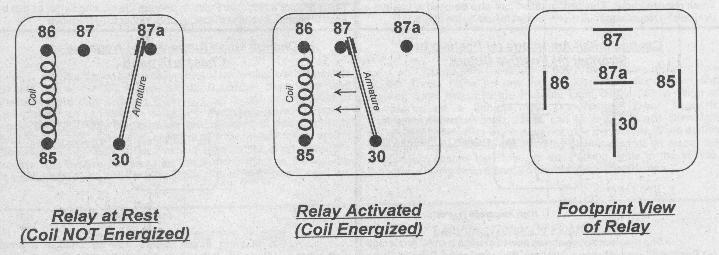

In the views above, note the five terminals, or

"pins." A relay's operation is really very simple. To understand its

operation, consider the relay as having two sections - the coil, pins 85 and 86; and the

contacts, pins 30, 87, and 87a. When Negative Ground is supplied to one end of the

coil, and Positive Voltage is supplied at the other end, the coil creates a magnetic field

which activates the relay. This magnetic field attracts the armature, which is

attached to pin 30 with a flexible joint, just like a hinge. Inactivated, or

"at rest," the armature connects pin 30 to pin 87a. When the relay is

activated, the armature connects pin 30 to pin 87. The terms used to describe the

contact points are this: pin 30 switches between pins 87a and 87, so it is

"Common" to both and is usually referred to as COM. In the relay's normal

condition, at rest, pin 30 is connected to pin 87a, making pin 87a "Normally

Closed" or NC. Pin 87 is not connected to pin 30 at rest, so its status is

"Normally Open" or NO. This type of relay is defined as "Single Pole

Double Throw" or SPDT. This term means that the single armature terminal (or

pole, pin 30) can be connected (or "thrown") to two other terminals, pins 87a

and 87. The SPDT relay is one of the most useful configurations due to its

flexibility - it can be used as a switching device, to isolate circuits, to interrupt

circuits and to interrupt and switch at the same time.

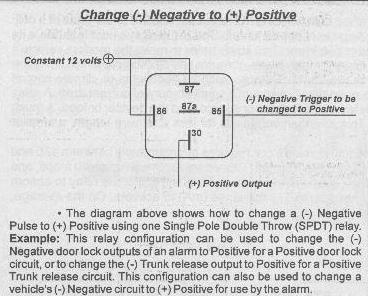

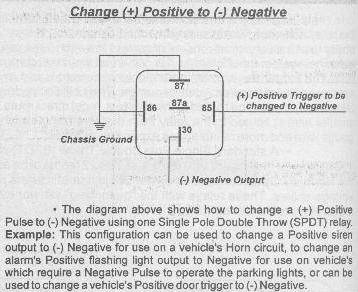

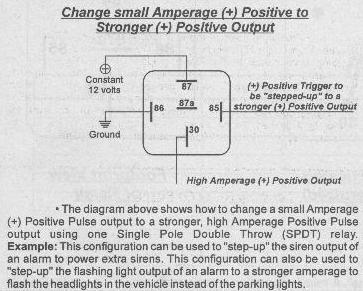

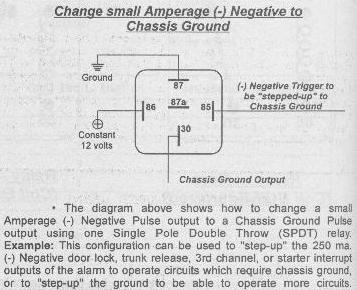

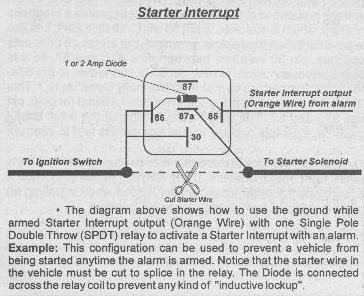

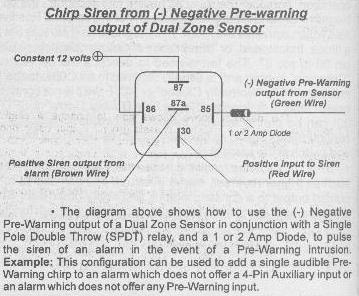

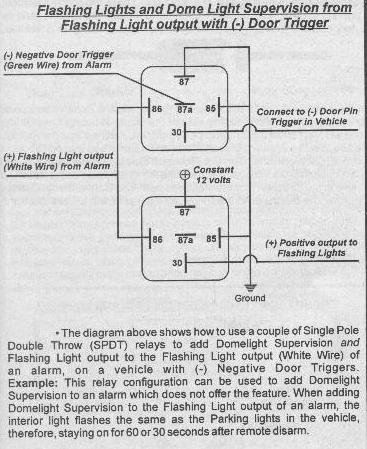

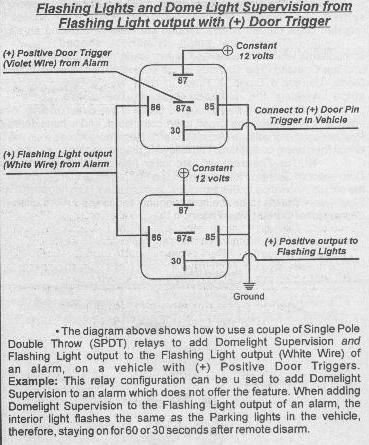

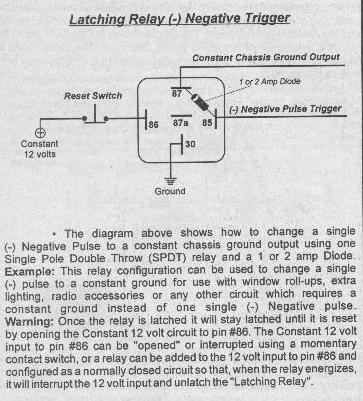

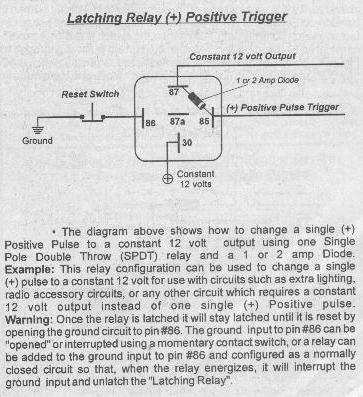

Here are some relay diagrams which show how to use

relays to perform many functions such as trigger reversal, starter interrupt, add dome

lights to flashing light output of alarm, using latching relays to change a pulsed output

to a constant output, and many other uses. These relay configurations can be very

helpful when installing an alarm, remote start, or keyless entry to perform different

functions in the vehicle on which they are being installed.

There, if you aren't a relay expert after all that,

you need help!!! :-)

Understanding Diodes

Diodes are electronic components which have the

ability to allow current flow in only one direction. There are many electrical

systems and electrical components and circuits which use Diodes to prevent a back feed

between circuits, to isolate circuits, and to prevent some current spikes. Diodes

are ideal for isolating an alarm, keyless entry system, or remote start from the factory

wiring in a vehicle.

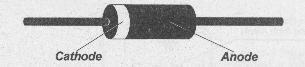

Diodes are small cylindrical shaped components

which are consisted of two leads, the Anode and the Cathode. The Cathode is the

striped side of the Diode. Usually a Diode is black in color with a Gray stripe marking the Cathode side of the Diode.

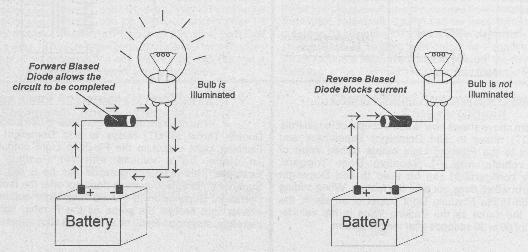

Current will flow through a Diode in one direction

only. When the Anode side of the Diode is facing towards the Positive source of

voltage, it WILL allow the circuit to be completed, and is considered Forward Biased.

If the Cathode side of the Diode is facing towards the Positive source of voltage

(Anode towards Negative source), then the Diode will NOT allow the circuit to be

completed, it will instead prevent the circuit. According to Electron Flow, current

flows from negative to positive in the direction that the electrons flow. The

Conventional Current Flow theory seems to be the most popular and is used more often,

therefore, the diagrams in the following examples will be based on the Conventional Flow

Theory.

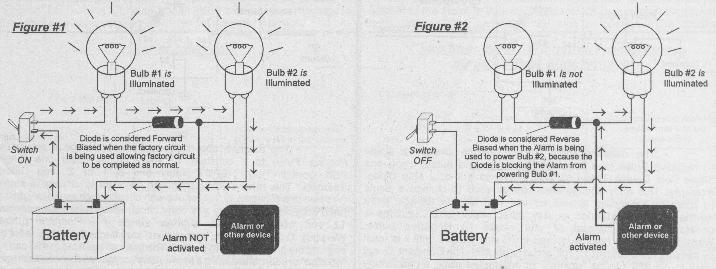

The following diagram illustrates how a Diode can be

added to a factory circuit to isolate the Alarm or other device so that, when activated,

it will power just one of the components in a circuit instead of all the components in the

circuit. In this case the Diode could actually be considered Forward or Reversed

Biased, depending on the actual circumstances of the circuit. For example: In

the circuit illustrated below, the factory switch controls both bulbs when the switch is

in the on position and the alarm is not activated. The Diode shown in Figure #1

could be considered Forward Biased because the current is flowing through the circuit when

the switch is used to power the circuit. The same Diode in Figure #2 could be

considered Reverse Biased, when the switch is off and the alarm is activated, because it

is allowing the alarm to power only one bulb and is blocking the current from back feeding

to the other components in the circuit.

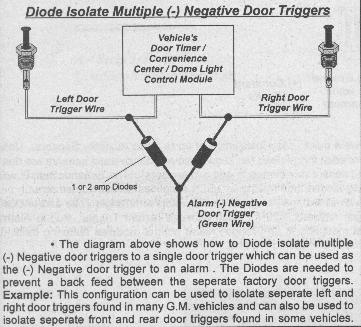

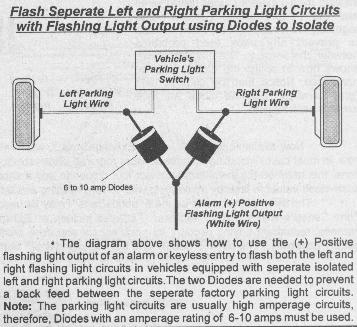

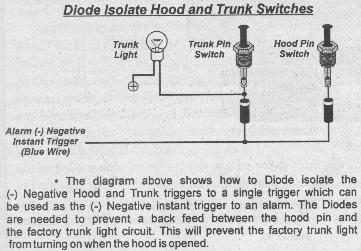

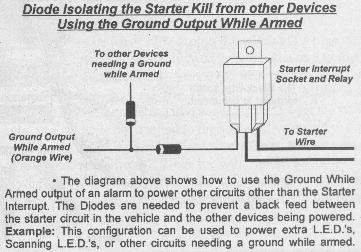

Diodes can be used in many different configurations

to perform such functions as: Using an alarm's or keyless entry's unlock output for

factory alarm arm and disarm, Diode isolating door triggers in a vehicle, using one output

to power two different circuits without back feed between the two circuits, Diode

isolating trigger circuits or components, and many other uses. For examples and

configurations of how Diodes can be used to perform these features on various different

circuits in an alarm, keyless entry, or remote start application, see the following

diagrams.

Wire Crimping

Insulated crimp-type terminals can make good

connections, but the must be done properly. Crimp terminals come in many styles, and

are sized to match wire gauge. Matching the correct size terminal to the wire gauge

is very important, and many failed crimp connections can be traced to the failure of doing

so. Insulated crimp connectors are color-coded to match the wire gauge range that

the connector is designed for. Most crimpers are also coded with matching colors to

identify the correct "nest" that the connector is squeezed in. Pink

terminals are for 20 and 18 gauge wire, and are crimped in Red nest on the crimping tool.

Blue terminals are for 16 and 14 gauge wire, and are crimped in the Blue nest on

the crimping tool. Yellow terminals are for 12 and 10 gauge wire, and are crimped in

the Yellow nest on the crimping tool. Never "shave" a wire by cutting some

of the wire strands so that it will fit into a smaller terminal. Whenever an

existing wire is being lengthened, the additional wire would be at least one wire gauge

size larger.

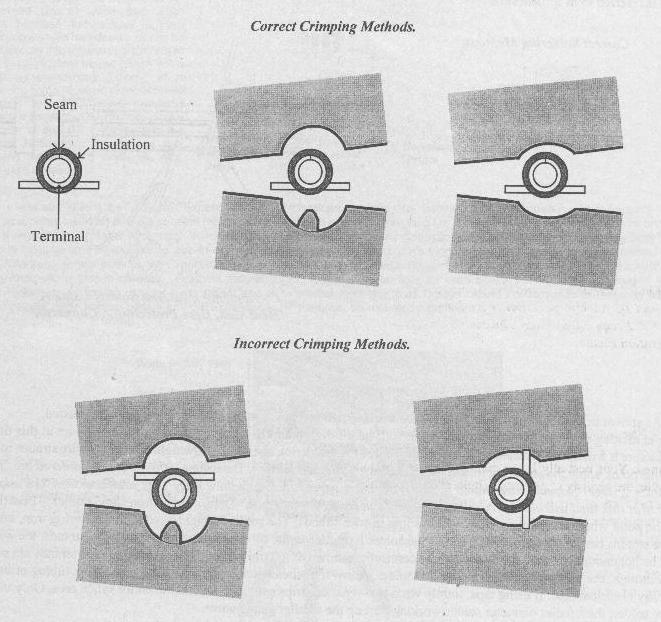

Another reason for failed crimp connectors is failing

to "crimp across the grain" of the connector. Carefully examine the crimp

area of a connector. You may have to look inside the barrel where the wire is

inserted. You'll notice a seam in this area. The jaws of the crimping tool

should be applied directly across this seam and not at an angle.

|