I'll first start off by

describing a little about just what this kit does, the differences between the Full

Install and the Basic Install and also show you how this compares to a stock 93 to 96

Camaro Tail light.

Listed below are the different sections of

the tail light

Below is the layout for a stock tail light

| Parking light |

Parking light

Brake light

Turn signal |

Backup light |

| Parking light |

Below is the layout you'll have if

you choose the Basic Install

(B) = Bright Filament (D) = Dim Filament

Turn signal 3rd

Brake 3rd |

Parking light (D)

Turn signal 2nd (B)

Brake 2nd (B) |

Backup light |

Parking light (D)

Turn Signal 1st (B)

Brake 1st (B) |

Below is the layout you'll have if

you choose the Full Install

(B) = Bulb Bright Filament (D) = Bulb Dim Filament

Parking light (D)

Turn signal 3rd (B)

Brake 3rd (B) |

Parking light (D)

Turn signal 2nd (B)

Brake 2nd (B) |

Backup light |

Parking light (D)

Turn Signal 1st (B)

Brake 1st (B) |

As you can tell from above, by doing

either the Full Install or Basic Install you'll end up (per side) with 3 sequenced brake

lights instead of just the 1 in the middle and 3 sequenced turn signal lights instead of

just the 1 middle. You can also see there isn't that much of a difference between

the Basic and Full Install... the difference being with the Basic install the outer

section isn't lit when the parking lights/head lights are on where as with the Full

Install it is. I opted for the Full Install because I wanted all three sections to

be on when the lights were on.

|

| These "blah" tail lights are about to go

away and be transformed into something a bit unique and quite the attention getter. When I started the install of these on my Camaro, I was a bit concerned

they may appear to be a bit "ricey" if you know what I mean. BUT, that is

FAR from the case. These add a very nice touch and are no where near a

"rice" mod IMO. |

|

|

|

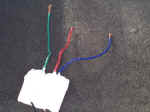

| NOTE: WebElectric's sequencers are

much more "professional" looking and come in a nice case. The pictures

here are of the sequencers I purchased from Damion several years ago. Included with the Basic Kit are:

- Two sequencer modules. These are the "brains" of

the operation and what control the sequencing.

- Two GM 90 degree double contact sockets.

- One flasher. This flasher is actually a hazard flasher and

will provide a slightly slower flash rate which allows for all the lights to come on

during the sequencing.

In addition to what is included in the kit you will, at a minimum

need a sharp knife and electrical tape. This is at a bare minimum!!! I highly

recommend instead of a knife that you invest in a pair of wire strippers and cutters if

you don't already have some. Also, instead of electrical tape, I used blue Scotch

Lok connectors (pictured later) for making splices and plastic caps (butt end connectors

will work too) for connecting two wires. If using the Scotch Lok connectors you'll

need a pair of pliers to crimp them in place. Extreme people may whip out the soldering

gun and solder everything and then shrink wrap it but these are just tail lights so for me

the solder and shrink wrap are a bit excessive ;-) |

|

|

|

| I will detail here both the Basic and the Full

Install. The first method is the Basic Installation which is quick, easy, and can be

performed with basic hand tools. The second method is the Full Installation method.

See above for a description of description of the difference between the two install

methods. The Full Install is a bit more time consuming and requires modifying your

the tail light assembly and purchasing more parts for the install. If you didn't

purchase the Full Install Kit from the get go but would now like to do this, it will

require two more of the GM sockets shown above and two 2057 bulbs. I bought the

sockets (model number 85832) at Auto Zone for $4.99 each and a package of two 2057 bulbs

for $1.79. If you don't have an Auto Zone near you the sockets may be a different

part number... that's ok, you're just looking for a GM 90 degree dual contact socket like

shown in the picture. You'll also need a Dremel and a cutting type drill bit. So, if

you bought the Basic Install Kit and now are deciding you want to do the Full Install,

it's going to cost you an additional $12 or so (assuming you already have a Dremel).

Damion only charges $12 more for the Full Install Kit plus he modifies the sockets

for you... not a bad deal at all :) |

(Wrong bulbs pictured... need 2057!)Will

get new picture! LOL! |

|

|

| We need to gain access to the back side of the tail

lights so we can remove them. To do this you will need to remove the two side panels

pictured here. You do not need to remove the back "carpet" piece as you

can just bend that out of the way as needed. The driver side

panel is removed by just pulling up on it. It is held in place by ribbed plastic

pins. After you get the driver side panel off you may notice the plastic ribbed pins

stayed in the metal holder portion of the car. If this is the case, just remove them

and place them back in the plastic panel. Your spare tire is stored under the

passenger side panel so its removal is a bit different. You need to align the three

screws as pictured (only two shown) and the panel will just lift off. |

|

|

|

| With the two plastic panels removed you will now need

to remove your spare tire. You may not NEED to but it will sure make getting the

tail light out much easier :) In my case I also had to pull out my Stealth Box. |

|

|

|

| With my spare tire and Stealth Box removed I now had

access to the plastic retaining knobs which hold the tail light in place. Just

unscrew the two plastic knobs on each side and you will then be able to remove the tail

lights. |

|

|

|

| With the retaining knobs removed you will be able to

just pull the tail light assembly straight out and rest it on the rear bumper cover.

I pulled the driver side out first then the passenger side. After I removed

the driver side I thought it would be a good idea to place a rag down so as to not scratch

my bumper cover :) Right after I took the picture I did place a rag on the bumper

for the driver side :) For the install I'll refer to the

different lights as the inner, middle, and outer. I have them labeled in the bottom

picture here and you can also look near the top of this page for a description. The

backup light is easy to tell because it is the only socket which is green! |

|

|

|

| The top picture here are the driver side light

sockets removed. The bottom picture are the passenger side sockets removed. The only difference between the two sides is on the MIDDLE socket.

The power wire on the driver side middle socket is YELLOW and

on the passenger side this same wire is GREEN. Other

than this difference the process for hooking the modules and sockets up will be the same

for both sides. Therefore, I'll often times only detail the install for one side. |

|

|

|

| The first thing we are going to do is work on the

middle socket. This socket will not need to be changed because it is the current

turn signal socket and already is the proper 3 wire socket. The

first picture is one of the Blue Scotch Lok connectors I mentioned earlier. These

work great for making splices as you don't need to cut the wire you are trying to splice

in to. If using the Scotch Lok connector cut the RED

wire on both sequencer modules as shown so there is no frayed wire showing. |

|

|

|

| On the driver side locate the YELLOW

wire on the middle socket and place the Scotch Lok connector over the yellow wire as

shown. If you are not using these connectors cut the YELLOW

wire a couple of inches up from the socket. |

|

|

|

| On the driver side, slide the RED

wire of the sequencer into the Scotch Lok connector around YELLOW

wire and crimp it down with a pair of pliers. If you are not using the Scotch Lok

connector then twist together the two YELLOW wires and the RED sequencer wire (I'll assume you know that you need to strip

back a portion of the insulation on the wires ;). The idea is the same as with the

Scotch Lok connector... just more difficult :) Do the same

on the passenger side middle socket but instead of a YELLOW

wire you should have a GREEN wire. Make your

connections to this GREEN wire as shown in the bottom

picture.

This completes the work on the middle socket. |

|

|

|

| Now we are going to work on the inner socket.

Notice your current inner socket looks about like the middle one we just worked on BUT

this inner socket has only two wires. That won't work with our sequencer so we need

to get rid of this socket. Cut both the BLACK and BROWN wires of the socket as shown here and put this socket aside.

Repeat this on the passenger side. |

|

|

|

| Now you are going to use the sockets supplied with

your kit. Grab one of these sockets. It has three wires... a BLACK, WHITE, and

BROWN. Connect the socket's BROWN

wire to the BROWN wire that was for the socket we just cut

off. Connect the socket's WHITE wire to the GREEN wire

of the sequencer module. Connect the socket's BLACK wire to the BLACK wire for the

socket we just cut off and also the BLACK wire from the sequencer module. It'll look

similar to the picture here. Remember, if you aren't using caps like I am then

you'll need to tape up your connections with electrical tape. Take the bulb out of

the socket you just cut off and insert it into your newly installed socket. NOTE:

When placing a bulb in these new sockets it's not a bad idea to also put some

"bulb grease" in there. It is a grease that prevents corrosion. You

may notice this grease in the factory sockets. You can purchase this grease in a

packet at your auto parts store for about $1 :) It's not 100% necessary but a good

idea! Repeat this for the passenger side.

This completes the inner socket. All that is left now is the

outer socket! |

|

|

|

| If you are doing only the Basic Installation continue

reading on how to wire up the outer light. If you are doing the Full Installation,

skip to the next set of instructions. I didn't do the Basic

Installation so don't have many pictures but it isn't difficult.

On the outer socket (the smaller one) slide a Scotch Lok connector

over the BROWN wire. If you are not using these

connectors, cut the BROWN wire about 2 inches up from the

socket. Do not cut the black wire!

Insert the BLUE wire from the

sequencer module into the Scotch Lok connector on the BROWN

wire and crimp it in place. If not using these connectors then twist together your

two BROWN wires and the BLUE

sequencer wire to make the splice.

Repeat this on the passenger side.

For the Basic Installation you are about done and can now skip

down to the section where you'll connect the sockets into the light assembly. |

BASIC

INSTALLATION

ONLY

|

|

|

| Full Installation Only:

Locate the small outer socket and cut it off as shown in the lower picture.

We will be replacing this socket with one of the new 85832 GM sockets you purchased from

the auto parts store or got in the Full Install Kit. As

stated above in the pricing section, doing a Full Install places a dual filament bulb very

close to the actual tail lamp red housing. I'm not saying this will happen but

rather there is a possibility your tail light could get a very small dimple in it due to

the heat from this dual filament bulb. Just be aware of this and make sure you

modify the hole in the housing so the bulb is as far away from possible from the edge of

the housing. |

|

|

|

| Full Installation Only:

Ok... now is where the fun begins :) We need to be able to install the new GM

socket in the area where the small socket currently resides. As you can see, it

obviously won't fit as is and the hole will need to be modified. I decided to rather

than just "wing it" to make a template. I took a sheet of ink-jet paper

and pushed it over a tab near the middle socket hole. I then held the light assembly

up to a light source (the sun!) and traced the opening. You cut this out and there

is your template! |

|

|

|

| Full Installation Only:

The first thing you'll notice is there is a plastic brace which is slightly in the

way. You can see this in the first picture. For all

the "hacking" I did on my tail light assembly I used a cutting type drill bit

like shown here. It looks like a standard drill bit but it's not... it is made for

cutting plastic just like we need to do here.

The bottom picture shows the brace removed. |

|

|

|

| Full Installation Only:

With the brace removed take your template and tape it in place. Now this is

VERY important. This is basically NO room for error here because it is a very tight

fit. Because of this you need to place your template NOT directly over the current

hole but rather as far down and to the inside as you can. If you don't do this your

socket will hit the metal part of your car and your tail light assembly will not go all

the way in. In the picture you can see where my template is not centered on the

hole. When taping on your template you need to take into consideration that once the

socket is inserted into the hole it is TWISTED to lock in place. You need to take

into account this "twist" when aligning your template. This will take some

thinking and eyeballing on your part so take your time here and double check what you plan

to do. Once the template is in place, trace around it with a Sharpie marker or

something you can see. No use your Dremel and cut the hole to the proper size.

Another very important note here is that you can always make the hole bigger... you

can't easily make the hole smaller again!!! So, whatever you do, error on the size

of SMALL. Cut out a little less than you think you need to then test fit with the

socket. If it is too big, GOOD, because all you'll need to do is place the socket

over the hole and see where you need to remove more plastic. If it just falls in

then you screwed up and may need to purchase a new tail lamp assembly and you don't want

to do that so cut small!!! Take note that on the driver side socket I ended up

removing the "tab" on the side with my Dremel. You can see it

"missing" in the picture to the right. If you purchased the Full Install

kit your sockets should already come modified for you. The

last two pictures show mine complete with the new sockets in place. Once you get

yours in place and holding tight like mine here you will need to test fit them. When

you are test fitting them you will see what I meant by there is very little room here to

mess up. You may need to slightly rotate the socket one way or the other but that

shouldn't hurt so long as it stays tight in place. If you happened to mess up to the

point that no matter how you rotate your socket you can't get the tail light to test fit

properly because the socket is hitting the car, there may be hope :) You can modify

the socket and hack away at the plastic with your Dremel to reduce its size. If you

need to you can take the clear plastic cover entirely off and fill the area with silicone

caulk. |

|

|

|

| Full Installation Only:

With the hard part out of the way all that is left is to connect the socket. Connect the socket's BROWN wire to the BROWN wire that was for the socket you just cut off. Connect

the socket's WHITE wire to the BLUE wire of the sequencer

module. Connect the socket's BLACK wire to the BLACK wire for the socket you just

cut off. It'll look similar to the picture here.

All electrical connections are now complete! |

|

|

|

| With all electrical connections made it is now time

to put the assembly back together. Note,

the sockets will be arranged differently than they were before! If

you notice this, you aren't confused... it's supposed to be like this :)

The socket which has the RED

sequencer module wire connects to the inner socket hole.

The socket which has the GREEN

sequencer module wire connects to the middle socket hole.

The socket which has the BLUE

sequencer module wire connects to the outer socket hole.

The backup light socket goes back into the same hole and when

finished all sockets should look like this picture. |

|

|

|

| Now you can change out the flasher. You'll need

to remove the panel under the steering wheel. Once this panel is removed the flasher

is located to the bottom right. The easiest way to find the flasher is to turn on

the ignition and turn on your turn signal then follow the clicking noise. Be careful

here because there are two flashers. One of the signals and one for the hazards...

you don't want to replace your hazard flasher! Once found, turn the ignition back

off, remove the flasher and install the new flasher which was supplied in the kit. |

|

|

|

| Check out your connections! Turn on

your hazards and check your lights to be sure they all light up in sequence. Have

someone press the brake and make sure the brake lights work and initially light up in

sequence. Turn your car on and check the signaling to the left and then to the

right. If one or more bulbs do not light up, double-check the connections to that

bulb. Also check the power and ground connections going to the sequencer

module. You'll also want to check to make sure your bulb didn't just burn out.

That happened to me... for some reason my inner driver side light didn't work, I checked

all connections and all seemed fine. I finally decided to change the bulb and it was

the bulb... whoops :) Enjoy your new sequencer lights and

all the comments you'll get from them! |

|

|

|

|